Cooling, or air conditioning, is more complicated than heating. According to the US Department of Energy, heating and cooling systems emit over a half billion tons of carbon dioxide into the atmosphere each year. Also, most of our buildings made of the concrete, whose production is a major source of carbon emissions. And once it’s done, heating and cooling buildings become a major energy sink.

One good way to reduce the amount of cooling a building needs is to make sure it reflects away infrared radiation. Passive radiative cooling materials are engineered to do this extremely well.

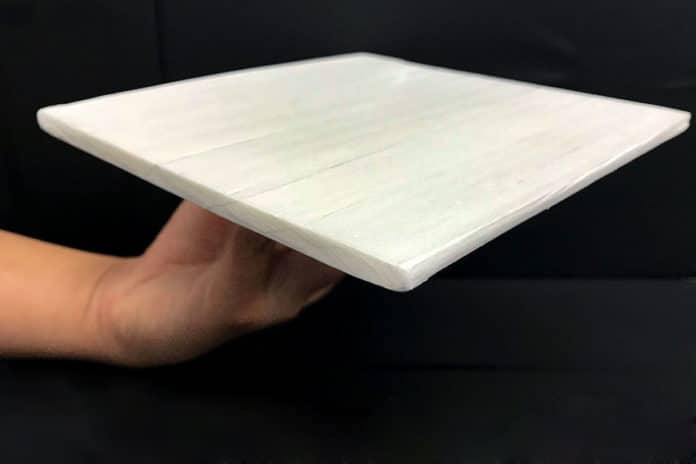

Now, a new type of wood that radiates heat into space could offer some relief. The material, if used on a building’s exterior, could drop a building’s temperature as much as 10°C and reduce cooling costs as much as 35%.

Liangbing Hu, a materials scientist at the University of Maryland and his colleagues created this material by removing the ‘lignin’ from natural wood using hydrogen peroxide.

Well possibly, the houses made of high-tech wood could help us stay cool and also reduce carbon emissions by cutting energy used on air conditioning.

High-tech cooling wood

Lignin is a component of the cell walls in trees, that acts as a glue holding the straw strands together. Lignin is a strong emitter of IR light.

The team removed this from the wood by simply soaking the basswood in a solution of hydrogen peroxide, which chops normally long lignin molecules into small fragments. The fragments diffuse out of the solution and can be washed away. The team then used a hot press, an industrial vise for making wood composites, to compress the remaining cellulose and hemicellulose components together. The result was an engineered wood with eight times the strength of natural wood.

In addition, the cellulose in the wood reflects visible light and only absorbs very low levels of near-infrared light. It simply means the cooling wood reflects most of the components of sunlight right back to the environment.

As a result, a building made from this material would transmit barely any heat indoors. The team also found that the material can absorb heat produced indoors, which is emitted at a different wavelength range to sunlight. During cooler nights, the wood helps release the heat outside, making it useful day and night.

It could reduce air conditioning costs:

If this material were applied to the outsides of buildings in the warm climates, the passive cooling effect could reduce air conditioning costs by as much as 35%, the researchers reported in the journal Science.

Hu says the cooling wood is very dense and has a tensile strength of around 404 megapascals, making it 8.7 times stronger than natural wood and comparable to metal structure materials including steel.

But, as the cooling wood restrict the heat from the sun from getting indoors, so it could add additional heating costs during winter. Hence, Hu says the material is best suited for warm areas with long summers and short winters.

This multifunctional, scalable cooling-wood material holds promise for future energy-efficient and sustainable building applications, enabling a substantial reduction in carbon emission and energy consumption.